- 1 (403) 652-8778

- sales@derex.ca

- Mon - Fri: 9:00 - 18:30

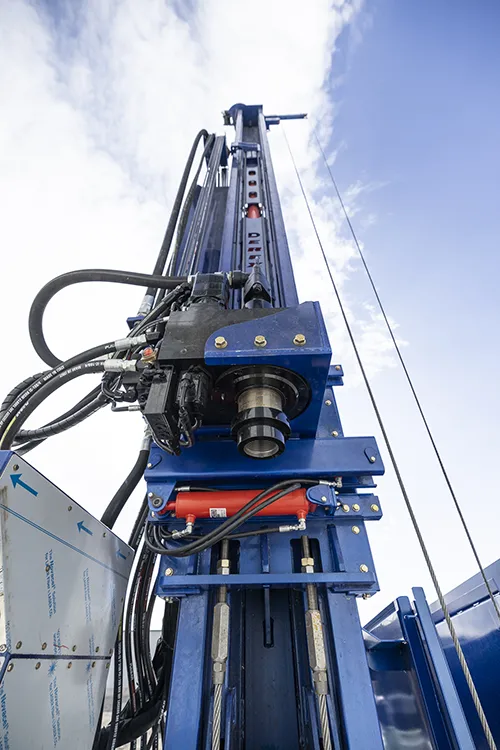

Dual Rotary Drilling Rigs

Drill cased holes quickly and easily with our Dual Rotary Drilling technology! When compared to conventional drilling methods, Dual Rotary Drilling is by far the fastest and most effective technique of drilling unconsolidated formations (sand, gravel, cobbles, and boulders). The versatility of the Derex Dual Rotary Drilling rigs will allow you to drill more holes and expand the capabilities of your drilling operations.

1340 DR

The Derex 1340-12 Dual Rotary drilling rig is designed to be light-weight so anyone can drive it without requiring a CDL.

1340-250 DR

The 1340 Dual Rotary drill carried by the Acela Monterra 4X4 on a 12′ deck. The 1340-12X is both compact and off-road capable.

1340-350 DR

Enjoy the legendary performance and reliability of the 1340 drill on a 14′ deck, which allows room for onboard air.

Like the king of the dinosaurs, the T-REX is designed to be the king of geothermal and exploration drilling. This beast of a track drill will dominate the toughest terrain and conquer the most challenging drilling conditions with ease.

Why you need a Derex Dual Rotary Drill

- Flexibility – Derex Dual Rotary Drilling Rigs can adapt to various drilling processes such as mud, reverse circulation, and flooded reverse circulation. With its exceptional flexibility, the DR allows you to explore new applications and venture into areas that were once deemed inaccessible. Dual rotary drilling ensures your confidence in successfully drilling the hole on the very first attempt!

- Straight Holes –Dual rotary drilling technology consistently delivers straight holes, which makes it ideal for water wells, geothermal and exploration drilling. A straight hole will reduce stress on the casing and casing welds, which minimizes the risk of breaking a weld. This also makes the installation of screens and pumps easy in water well applications.

- Speed – Dual rotary drilling is by far the fastest method of drilling and tripping available today. When compared to traditional drilling methods some companies have reported a 50% increase in production

- Casing Extraction –The powerful lower rotary drive is efficient at pulling back casing, which simplifies the process of exposing well screens or abandoning a well.

- Discharge Control – The cuttings are directed through a discharge swivel, which allows you to safely control the location of the dumping or monitoring.

- Noise Reduction – When compared to traditional drilling methods, dual rotary generates significantly less noise, allowing you to expand into areas sensitive to sound pollution.

- Greater depth capacity – Dual rotary drilling rigs can reach significant depths, making them suitable for various applications, including water wells, geothermal installations, and environmental drilling projects. Derex DR Drills have reached as deep as 1800 feet.

- Ease of Maintenance – The Derex DR rigs come with a hydraulic feed system that is directly linked, eliminating the need for maintenance of chains, sheaves, or sprockets. This unique feed system ensures there is no load on the mast crown, enabling a straightforward and lightweight mast design without compromising on pullback capability.

- Equip Conventional Tooling – Dual rotary drilling doesn’t require any different drilling tools. Equip your drill string with conventional DTH hammers, tricone bits or drag bits.

OTHER DRILLING RIGS

Introducing the Derex 2630-22 M.A.T.H. drilling rig, mounted on a Peterbilt 567 for a seamless blend of power, reliability and comfort. The Derex 2630-22 drilling rig has bragging rights with 26’ of stroke, 30,000 to 70,000 lbs of pull back and up to 8,000’/ lbs of torque. This powerful drilling rig features NO crown loading, and has a top drive that slides both ways off the hole center to give winches a clear hole, allowing you to pull rods and casing quickly and efficiently!

Introducing the Derex 2630-22 M.A.T.H. drilling rig, mounted on a Peterbilt 567 for a seamless blend of power, reliability and comfort. The Derex 2630-22 drilling rig has bragging rights with 26’ of stroke, 30,000 to 70,000 lbs of pull back and up to 8,000’/ lbs of torque. This powerful drilling rig features NO crown loading, and has a top drive that slides both ways off the hole center to give winches a clear hole, allowing you to pull rods and casing quickly and efficiently!